[Paper Width Adjustment]

Overview

Adjust the alignment plate position in the crosswise direction of the Relay Unit RU-510 to eliminate misalignment of punch holes.

This function is available when paper is conveyed while it remains bent or skewed against the next-stage finisher.

Specifications

Category | Adjustment / Maintenance | ||

Location | Machine | Touch Panel | |

Printer driver | - | ||

Application | - | ||

Required options | Relay Unit RU-510 | ||

Required items | - | ||

Setting items | Keypad | Used to enter numeric values. | |

[Clear] | Returns the entered numeric value to "0". | ||

[Set] | Sets the numeric value entered using the keypad to the selected setting item. | ||

Remarks | - | ||

Reference | - | ||

Screen access | Touch panel - [MACHINE] - [Adjustment] - [Finisher Adjustment] - [Relay Stacker Adjustment] - [Paper Width Adjustment] | ||

Control panel - Utility/Counter - [Administrator Setting] - [System Setting] - [Expert Adjustment] - [Finisher Adjustment] - [Relay Stacker Adjustment] - [Paper Width Adjustment] | |||

Procedure

A sample is output. This section describes a sample with punch holes.

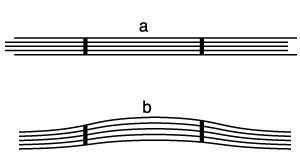

a: Misalignment occurs if the pitch of the alignment plate is wider than the paper width.

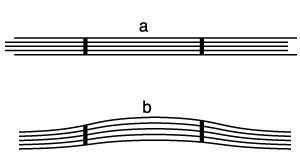

b: A distortion occurs in punch holes if the pitch of the alignment plate is narrower than the paper width.

Use [+ / -] to select the plus or minus of the numeric value. To change [Current Data], press [Set].

[-] To reduce the dispersion, [+] To reduce the misalignment

[Adj. Range:-20~+20 1step = 0.1mm]

To make adjustments, set the paper width adjustment value to the maximum (to reduce misalignment), adjust in the direction to reduce dispersion , and find a point at which the through hole of the punch holes is not misaligned.

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.