[Color Validation]

Overview

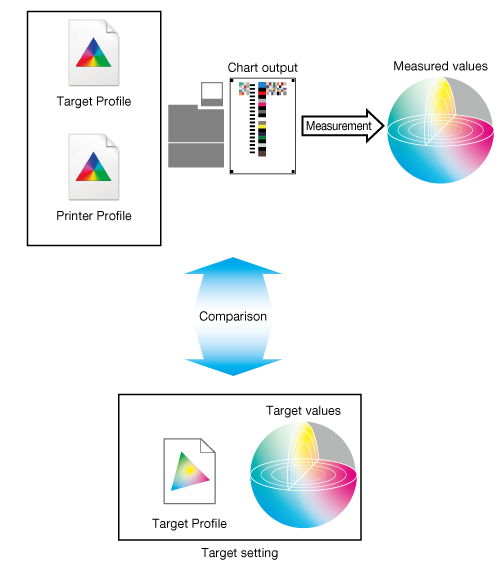

[Color Validation] is a function for evaluating current color reproducibility by measuring printed charts and comparing the actual output results (measured value) with the preset reference (target value). This function displays the result of comparing the measured value with the target value.

Implement Daily Adjustment Flow (High Precision) if the results of the comparison between the measured value and target value show that the color value discrepancy (ΔE) is outside of the allowable range.

- Intelligent Quality Optimizer IQ-501 is required to use this function.

- [Target Settings] must be created before performing [Color Validation].

- When printing successive jobs: 2 times a day before printing

- When printing a single job: before printing

Color Validation Implementation Flow

Follow the steps below.

Executing [Color Validation]: Touch panel

Execute [Color Validation] on the system's Touch panel.

- Intelligent Quality Optimizer IQ-501 is required to use this function.

For details about the procedure, refer to [Color Validation].

Executing [Color Validation]: PS Plug-in Driver

Perform [Color Validation] in PS Plug-in Driver.

- For details about how to use PS Plug-in Driver, refer to "PS Plug-in Drivers (What Is the PS Plug-in Driver?)".

For details about the procedure, refer to [Color Validation].

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.