Trimmer Unit TU-510

Name and Function of Each Component

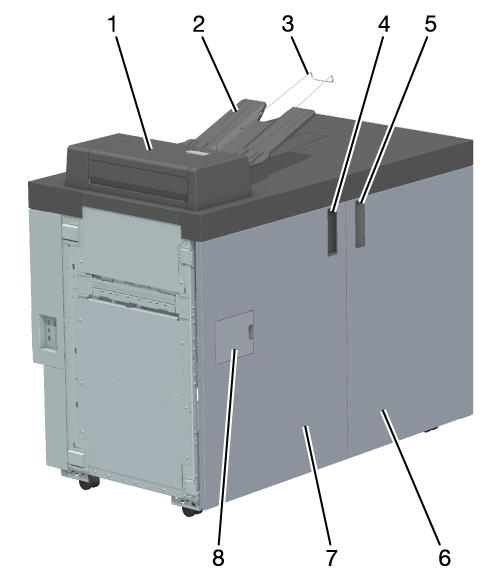

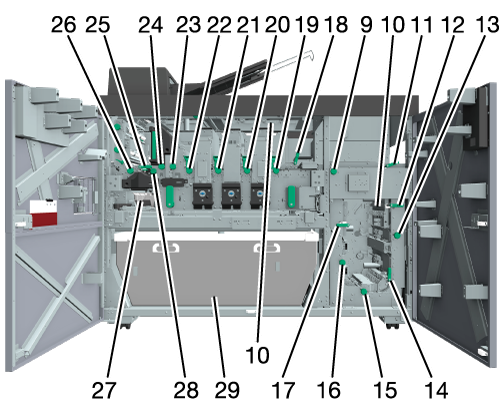

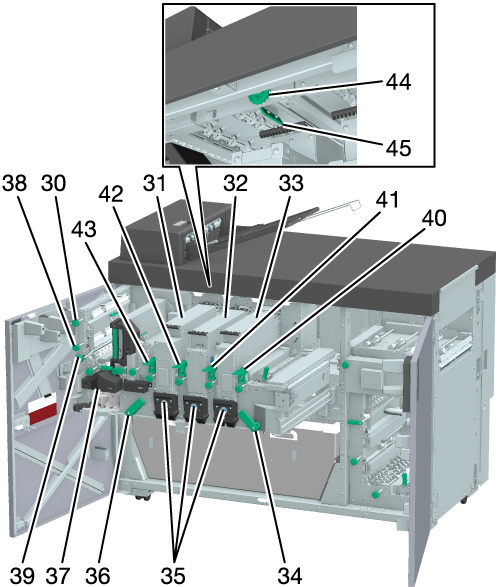

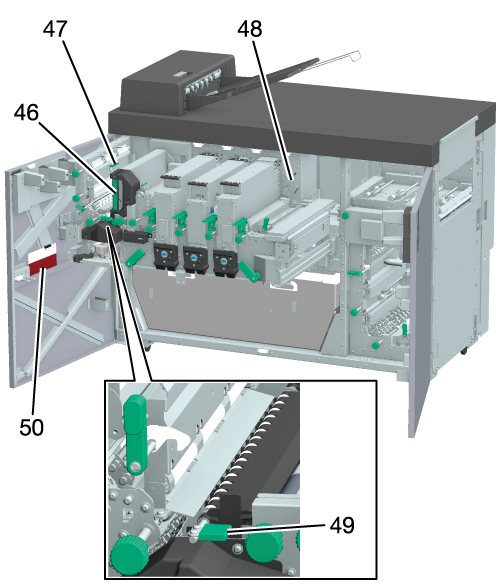

No. | Name | Description |

|---|---|---|

1 | Top cover | When clearing a paper jam, open the cover and remove the paper. |

2 | Secondary (sub) tray | Output the trimmed or creased paper or the paper delivered without processing. |

3 | Secondary (sub) tray extension | Pull out when ejecting large sheets of paper to Secondary (sub) tray. |

4 | Trimmer unit left side door knob | Used when opening Trimmer unit left side door. |

5 | Trimmer unit right side door knob | Used when opening Trimmer unit right side door. |

6 | Trimmer unit right side door | Open this door when clearing a paper jam or replacing an internal option. |

7 | Trimmer unit left side door | Open this door when clearing a paper jam or replacing an internal option. |

8 | Card tray door | Open this door when pulling out the Card tray. |

9 | Knob [TU2] | When clearing a paper jam, turn the knob to feed the paper through. |

10 | Banner Unit MK-764 (option) (2 locations) | Convey banner paper to the post-processing device, or invertconvey paper. |

11 | Lever [TU1] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

12 | Lever [MK1] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

13 | Knob [MK2] | When clearing a paper jam, turn the knob to feed the paper through. |

14 | Lever [MK3] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

15 | Knob [MK4] | When clearing a paper jam, turn the knob to feed the paper through. |

16 | Knob [MK5] | When clearing a paper jam, turn the knob to feed the paper through. |

17 | Lever [MK6] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

18 | Lever [TU3] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

19 | Knob [TU8] | When clearing a paper jam, turn the knob to feed the paper through. |

20 | Knob [TU10] | When clearing a paper jam, turn the knob to feed the paper through. |

21 | Knob [TU12] | When clearing a paper jam, turn the knob to feed the paper through. |

22 | Knob [TU14] | When clearing a paper jam, turn the knob to feed the paper through. |

23 | Knob [TU15] | When clearing a paper jam, turn the knob to feed the paper through. |

24 | Knob [TU16] | When clearing a paper jam, turn the knob to feed the paper through. |

25 | Lever [TU20] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

26 | Knob [TU21] | When clearing a paper jam, turn the knob to feed the paper through. |

27 | Card tray (Supplied with Job Separator JS-507) (Option) | Stack sheets cut to the card size. |

28 | Knob [TU17] | When clearing a paper jam, turn the knob to feed the paper through. |

29 | Trim scrap box | Pull out when discarding trim scrap. |

30 | Knob [TU25] | When clearing a paper jam, turn the knob to feed the paper through. |

31 | Trimmer Unit TU-504/Creaser Unit CR-103/Perforation Unit PE-101 (Optional) | Trimmer Unit TU-504: Slits the gutter horizontally for the paper feed direction. Creaser Unit CR-103: Attaches up-convex creases (folding lines) on paper. Perforation Unit PE-101: Attaches a perforation in the paper feed direction. * Only one of the following optional devices can be mounted on this system. |

32 | Creaser Unit CR-102/Perforation Unit PE-102 (optional) | Creaser Unit CR-102: Attaches down-convex creases (folding lines) on paper. Perforation Unit PE-102: Attaches a perforation in the paper crosswise direction. * Only one of the following optional devices can be mounted on this system. |

33 | Slitter unit | Trims paper in the paper feed direction. |

34 | Lever [TU4] | When clearing a paper jam or replacing an internal option, tilt the lever to the left and pull out the conveyance base. |

35 | Option fixing bracket | Turn to the left when removing an option. |

36 | Lever [TU5] | When clearing a paper jam or replacing an internal option, tilt the lever to the right and pull out the conveyance base. |

37 | Job Separator JS-507 (optional) | Cuts paper to the card size. |

38 | Knob [TU23] | When clearing a paper jam, turn the knob to feed the paper through. |

39 | Lever [TU22] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

40 | Lever [TU7] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

41 | Lever [TU9] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

42 | Lever [TU11] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

43 | Lever [TU13] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

44 | Knob [MK8] | When clearing a paper jam, turn the knob to feed the paper through. |

45 | Lever [MK7] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

46 | Lever [TU18] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

47 | Lever [MK24] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

48 | Lock lever [TU6] | Fixes the pulled-out conveyance unit. |

49 | Lever [JS1] | When clearing a paper jam, hold the lever, open the guide, and remove the paper. |

50 | Cleaning plate | Cleans the Line sensor. |

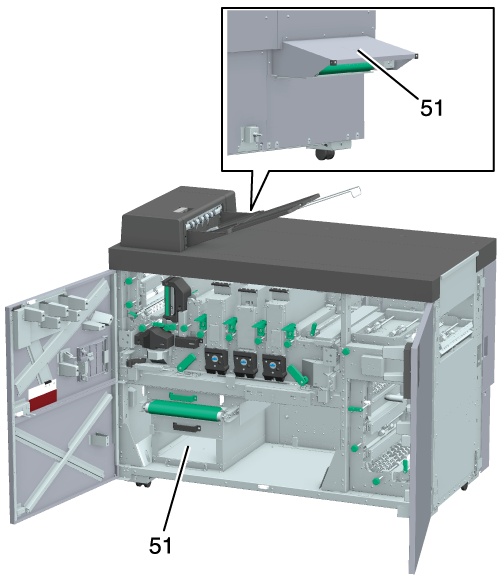

51 | Dust Box MK-765 | Discharges cutting scraps generated in the Trimmer Unit TU-510 to the outside of the machine. |

Specifications

Name | Trimmer Unit TU-510 | |

Type | Four-edge trimmer | |

Function | Through-path | Conveys paper to post-processing device without processing. |

Slit | Trims the top and bottom of paper in the paper feed direction. | |

Cut | Trims paper in the paper crosswise direction. | |

Four Edge Trim (Slit + Cut) | Trims the edge parts of paper in the paper feed direction and paper crosswise direction. | |

2-division mode (Slit + Cut) | Trims a single sheet of wide paper, and divides the paper into 2 sheets of A4 or 8.5 e 11. | |

Crease (Up Convex) (with Creaser Unit CR-103 mounted) | Attaches up-convex creases (folding lines) in the paper crosswise direction. | |

Crease (Down Convex) (with Creaser Unit CR-102 mounted) | Attaches down-convex creases (folding lines) in the paper crosswise direction. | |

Gutter Slit (with Trimmer Unit TU-504 mounted) | Slit the gutter parallel to the paper feed direction. | |

Perforation Cut (Horizontal) (with Perforation Unit PE-101 mounted) | Attaches a perforation in the paper feed direction. | |

Perforation Cut (Vertical) (with Perforation Unit PE-102 mounted) | Attaches a perforation in the paper crosswise direction. | |

Banner paper conveyance and reverse (with Banner Unit MK-764 mounted) | Corrects a banner paper skew and reversely conveys paper to the post-processing device. | |

Invert conveyance | Reverses paper, and conveys it to the post-processing device. | |

Subtray output | Ejects to Secondary (sub) tray. | |

Card Stack (with Job Separator JS-507 mounted) | Stacks the paper cut to the card size in the dedicated tray. | |

Through-path | Paper size | Standard size: SRA3 w, A3 w, B4 w, SRA4 w/v, A4 w/v, B5 w/v, A5 w/v, B6 w, A6 w, 7.25 e 10.5 w/v, 5.5 e 8.5 w/v, Foolscap* , 8K w, 16K w/v Custom: Widthwise 95 mm to 330.2 mm, lengthwise 133 mm to 1,300 mm / Widthwise 3.74" to 13", lengthwise 5.24" to 51.18" Fixed tab paper (back edge of tab during output is not guaranteed) *: Foolscap refers to 8.5 e 13 w, 8.25 e 13 w, 8.12 e 13.25 w, and 8 e 13 w sizes. |

Paper weight | 40 g/m2 to 450 g/m2 / 11 lb Bond to 119 lb Bond * The paper type is limited to 351 g/m2 to 450 g/m2 / 94 lb Bond to 119 lb Bond. * Paper of lengthwise 487.8 mm to 1,300 mm / lengthwise 19.2" to 51.18" is limited to 128 g/m2 to 300 g/m2 / 33 lb Bond to 81 lb Bond. | |

Slit | Paper size | Custom: Widthwise 140 mm to 330.2 mm, lengthwise 153 mm to 1,300 mm / Widthwise 5.51" to 13", lengthwise 6.02" to 51.18" Others conform to the through-path specifications. |

Paper weight | Thin paper to plain paper: 50 g/m2 to 61 g/m2 / 14 lb Bond to 15 lb Bond Plain paper to thick paper: 62 g/m2 to 400 g/m2 / 16 lb Bond to 106 lb Bond | |

Setting units | 0.1 mm | |

Slit independent setting | The slit width at the top or bottom can be set individually. However, the difference in cut size should be within 10 mm / 0.39". Only one-side cutting is not possible. | |

Cut | Cut range | Leading edge cut: 10 mm to 100 mm / 0.39" to 3.94" (Paper of 13 mm / 0.51" or more is cut multiple times.) Trailing edge cut: 10 mm to 13 mm / 0.39" to 0.51" |

Minimum cut length | 133 mm / 5.24" or more | |

Four Edge Trim (Slit + Cut) | Paper size | Before processing: Widthwise 140 mm to 330.2 mm, lengthwise 153 mm to 1,300 mm / Widthwise 5.51" to 13", lengthwise 6.02" to 51.18" After processing (Finishing size): Widthwise 120 mm to 314.2 mm, lengthwise 133 mm to 1,280 mm / Widthwise 4.72" to 12.37", lengthwise 5.24" to 50.39" |

Paper weight | 50 g/m2 to 400 g/m2 / 14 lb Bond to 106 lb Bond * Paper of lengthwise 487.8 mm to 1,300 mm / lengthwise 19.2" to 51.18" is limited to 128 g/m2 to 300 g/m2 / 33 lb Bond to 81 lb Bond. | |

2-division mode (Slit + Cut) | Paper size | A4 cutting of wide paper: Widthwise 313 mm to 330.2 mm, lengthwise 445 mm to 459 mm* / Widthwise 12.32" to 13", lengthwise 17.52" to 18.07"* *: Applied when the split width (width between cut sheets) is 5 mm to 13 mm. When split width is 0 mm: lengthwise 440 mm to 446 mm / lengthwise 17.32" to 17.56" 8.5 e 11 cutting of wide paper: Widthwise 299.4 mm to 330.2 mm, lengthwise 456.8 mm to 470.8 mm* / Widthwise 11.79" to 13", lengthwise 17.98" to 18.54"* *: Applied when the split width (width between cut sheets) is 5 mm to 13 mm. Split width = 0 mm: Lengthwise: 295.4 mm to 330.2 mm / lengthwise 11.63" to 13" |

Paper weight | Conforms to Four Edge Trim (Slit + Cut). | |

Crease | Paper size | Crease + Four Edge Trim Before processing: Widthwise 140 mm to 330.2 mm, lengthwise 153 mm to 1,300 mm / Widthwise 5.51" to 13", lengthwise 6.02" to 51.18" After processing (Finishing size): Widthwise 120 mm to 314.2 mm, lengthwise 133 mm to 1,280 mm / Widthwise 4.72" to 12.37", lengthwise 5.24" to 50.39" Crease + Four Edge Trim + Gutter Slit Before processing: Widthwise 210 mm to 330.2 mm, lengthwise 153 mm to 487.7 mm / Widthwise 8.27" to 13", lengthwise 6.02" to 19.2" After processing (Finishing size): Widthwise 85 mm to 153.1 mm, lengthwise 133 mm to 467.7 mm / Widthwise 7.64" to 13", lengthwise 18.41" to 51.18" |

Paper weight | Crease + Four Edge Trim 80 g/m2 to 400 g/m2 / 21 lb Bond to 106 lb Bond * Paper of lengthwise 487.8 mm to 1,300 mm / lengthwise 19.2" to 51.18" is limited to 128 g/m2 to 300 g/m2 / 33 lb Bond to 81 lb Bond. Crease + Four Edge Trim + Gutter Slit 128 g/m2 to 300 g/m2 / 33 lb Bond to 81 lb Bond * Coated paper is limited to 157 g/m2 to 300 g/m2 / 33 lb Bond to 42 lb Bond. | |

Crease processing method | By 1 sheet | |

Number of creases | 1 to 5 However, the following restrictions apply depending on the crease combination function. Fold & Staple/Half-fold: 1 crease Tri-Fold: 2 creases Quarto-Fold, Gate, Double Gate: 4 creases Crease only: 1 to 5 | |

Minimum crease interval | 1.0 mm / 0.04" | |

Crease processable range | 60 mm / 2.36" from leading edge to 60 mm / 2.36" from trailing edge | |

Setting units | 0.1 mm | |

Card mode | Paper size | For vertical 2 rows Before processing: Widthwise 210 mm to 330.2 mm, lengthwise 153 mm to 487.7 mm / Widthwise 8.27" to 13", lengthwise 6.02" to 19.2" After processing (Finishing size): Widthwise 85 mm to 153.1 mm, lengthwise 133 mm to 467.7 mm / Widthwise 3.35" to 6.03", lengthwise 5.24" to 18.41" For vertical 3 rows Before processing: Widthwise 287 mm to 330.2 mm, lengthwise 153 mm to 487.7 mm / Widthwise 11.3" to 13", lengthwise 6.02" to 19.2" After processing (Finishing size): Widthwise 85 mm to 99.4 mm, lengthwise 133 mm to 467.7 mm / Widthwise 3.35" to 3.91", lengthwise 5.24" to 18.41" |

Paper weight | Uncoated paper: 128 g/m2 to 300 g/m2 / 34 lb Bond to 81 lb Bond Coated paper: 157 g/m2 to 300 g/m2 / 33 lb Bond to 42 lb Bond Card cutting: 177 g/m2 to 300 g/m2 / 48 lb Bond to 81 lb Bond | |

Gutter width | 8 mm / 0.31" | |

Setting units | 0.1 mm | |

Perforation Cut | Paper size | Widthwise 140 mm to 330.2 mm, lengthwise 133 mm to 487.7 mm / Widthwise 5.51" to 13", lengthwise 5.24" to 19.2" |

Paper weight | 80 g/m2 to 140 g/m2 / 21 lb Bond to 38 lb Bond * Coated paper is limited to 100 g/m2 to 160 g/m2 / 27 lb Bond to 43 lb Bond. | |

Number of cuts | Paper feed direction: 0 to 2 Paper crosswise direction: 0 to 5 | |

Perforation cutting available range: | 30 mm / 1.18" from leading edge to 30 mm / 1.18" from trailing edge * The distance between perforation positions must be 120 mm / 4.72" or more. | |

Setting units | 0.1 mm | |

Banner paper conveyance and reverse | Paper size | Custom: Widthwise 140 mm to 330.2 mm, lengthwise 487.8 mm to 1,300 mm / Widthwise 5.51" to 13", lengthwise 19.2" to 51.18" |

Paper weight | 128 g/m2 to 300 g/m2 / 34 lb Bond to 81 lb Bond | |

Invert conveyance | Paper size | Custom: Widthwise 140 mm to 330.2 mm, lengthwise 153 mm to 900 mm / Widthwise 5.51" to 13", lengthwise 6.02" to 35.43" * Banner Unit MK-764 is required for invert conveyance of lengthwise 487.7 mm to 900 mm / lengthwise 19.2" to 35.43". |

Paper weight | 50 g/m2 to 400 g/m2 / 13 lb Bond to 106 lb Bond * Paper of lengthwise 487.8 mm to 900 mm / lengthwise 19.2" to 51.18" is limited to 128 g/m2 to 300 g/m2 / 33 lb Bond to 81 lb Bond. | |

Subtray output | Paper size | Conforms to the through-path specifications. |

Paper weight | Conforms to the through-path specifications. | |

Tray capacity (Secondary (sub) tray) | 100 sheets (80 g/m2 / 21 lb Bond, stack height 20 mm / 0.79") *Stack of 49 g/m2 / 13 lb Bond or less is not guaranteed. 1 sheet for paper of lengthwise 762.1 mm / 30" or larger. | |

Business card creation (Slit + Cut + Gutter Slit) | Paper size | Before processing: Widthwise 287 mm to 330.2 mm, lengthwise 400 mm to 457.2 mm* / Widthwise 11.3" to 13", lengthwise 15.75" to 18"* *: Applied when the split width (width between cut sheets) is 5 mm to 13 mm. Split width = 0 mm: Widthwise 287 mm to 330.2 mm, lengthwise 370 mm to 411 mm / Widthwise 11.3" to 13", lengthwise 14.57" to 16.18" After processing: Widthwise 85 mm to 91 mm, lengthwise 50 mm to 55 mm / Widthwise 3.35" to 3.58", lengthwise 1.97" to 2.17" |

Paper weight | 177 g/m2 to 300 g/m2 / 48 lb Bond to 81 lb Bond | |

Finishing standard size | 91 mm e 55 mm / 3.58" e 2.17", 85 mm e 55 mm / 3.35" e 2.17" or 89 mm e 51 mm / 3.5" e 2" | |

Number of finishing sheets per sheet | 21 sheets (when trimmed in 3 columns e 7 rows) | |

Top/bottom slit | 8 mm to 26 mm / 0.31" to 1.02" | |

Leading/Trailing edge cut | 10 mm to 13 mm / 0.39" to 0.51" | |

Gutter Slit | Paper feed direction: 8 mm (Fixed) Paper crosswise direction: 0 mm or 5 mm to 13 mm | |

Tray capacity (Card tray of Job Separator JS-507) | 504 sheets (168 sheets e 3 rows, 177 g/m2 to 256 g/m2 / 48 lb Bond to 68 lb Bond) 420 sheets (140 sheets e 3 rows, 257 g/m2 to 300 g/m2 / 69 lb Bond to 81 lb Bond) | |

Dimensions | 1,360 mm (W) e 747 mm (D) e 1,151 mm* (H) / 53.54" (W) e 29.41" (D) e 45.31"* (H) *: Maximum height, excluding the tray part. The top height is 1,020 mm / 40.16". | |

Weight | Approx. 272 kg / 599.66 lb Maximum mass including option: Approx. 328 kg / 723.12 lb | |

Power | DC 100 V, DC 5 V | |

Maximum power consumption | 900 W | |

Precautions on Output Face

Paper may not be output with the correct output face in the following conditions.

No. | Paper size | Print side | Post-processing (crease and slit) in Trimmer Unit TU-510 | Output destination | Face |

|---|---|---|---|---|---|

1 | Lengthwise 487.8 mm to 900 mm / 19.2" to 35.43" | Simplex | None | Secondary (sub) tray of Trimmer Unit TU-510 | Face Up |

2 | Lengthwise 487.8 mm to 900 mm / 19.2" to 35.44" | Duplex | None | Secondary (sub) tray of Trimmer Unit TU-510 | Face Down |

3 | Lengthwise 487.8 mm to 900 mm / 19.2" to 35.45" | Duplex | Available | Secondary (sub) tray of Trimmer Unit TU-510 | Face Down |

4 | Lengthwise 487.8 mm to 900 mm / 19.2" to 35.46" | Duplex | Available | Main tray of Finisher FS-541 or Output Tray OT-512 Secondary (sub) tray other than Trimmer Unit TU-510 | Face Down |

5 | Lengthwise: 900 mm / 35.46" or more | Simplex | None | Secondary (sub) tray of Trimmer Unit TU-510 | Face Up |

Precautions on the Secondary (sub) tray

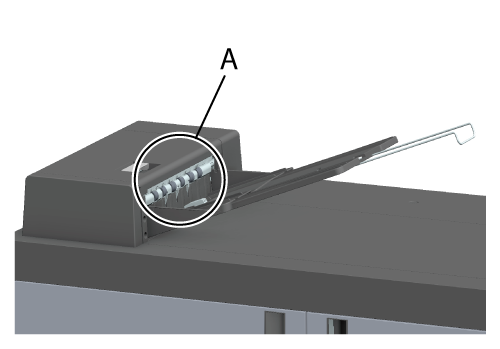

When removing paper from the Secondary (sub) tray of Trimmer Unit TU-510, be careful not to allow the paper to touch the revolving rollers (area A in the figure). The paper may be caught in the roller.

Was this information useful?

Thank you.

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.