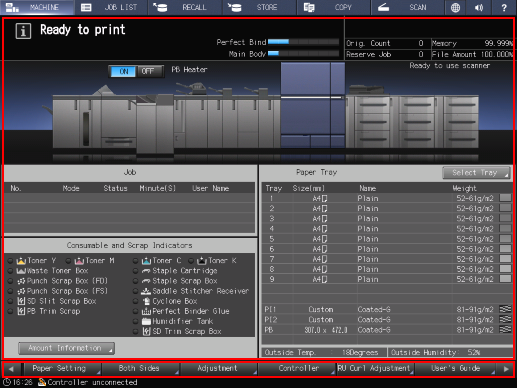

[MACHINE] Screen Layout

Overview

To display the [MACHINE] screen, press [MACHINE].

This area displays the status of the running system or the mounted optional devices in a visual and easy-to-understand way, enabling you to grasp the status of this system in real time.

You can configure various settings using keys at the bottom of the screen. Keys such as [Paper Setting] and [Both Sides] are generically referred to as "machine function keys".

- You can change the order of the machine function keys according to your preferences. For details, refer to [Machine Function Key Setting].

The displayed contents vary depending on models or optional devices mounted on this system. This section mainly describes the screens that are displayed when the following optional devices are mounted.

- Relay Unit RU-518m

- Intelligent Quality Optimizer IQ-501

- FoldingUnit FD-503

- Saddle Stitcher SD-513

- Perfect Binder PB-503

- Finisher FS-541

Screen and Description

Key name/area name | Description |

|---|---|

[MACHINE] | Displays the [MACHINE] screen. Displays the system status or the mounted optional devices in a visual and easy-to-understand way. |

Information display area | Reports the required operation depending on the system status or conditions. |

[Perfect Bind] / [Main Body] warm-up status bar | Indicates the warm-up progress while the perfect binder or machine is warming up. When the warm-up operation is completed, the status bar disappears. |

[Orig. Count] | Displays the count of printed originals. |

[Reserve Job] | Displays the number of reserved jobs. |

[Memory] | Indicates the amount of available space in the HDD memory of this system in "%" form. The unit of this value can be changed to "GB". |

[File Amount] | Indicates the amount of available space in the file system in "%" form. |

Scanner message | Displays the scan status of the original. This function is not displayed when a scanner is not mounted. |

Allows you to manually turn the PB heater [ON] or [OFF]. Displayed when Perfect Binder PB-503 is mounted. | |

Allows you to output a sample at any time when printing, and check the quality of printouts in real time. | |

Lowers the position of the Main tray of Output Tray OT-512. This is available when Banner Output Tray Unit MK-761 is attached to or detached from the Main tray. The option configuration for attaching Banner Output Tray Unit MK-761 is limited. For details, refer to Paper Output Options. | |

Displays the status of the job sent to this system in real time. | |

Allows you to check the following statuses. Toner status Replacement of the Waste toner box Staple supply to the mounted optional device Scrap disposal Water replenishment in humidifier tank Replacement of the [Cyclone Box] Toner level information | |

Displays setting information such as the paper size, paper orientation, and paper name for each paper tray. Also, this displays the temperature and humidity detected using the thermo-hygro sensor mounted on the system. | |

Machine function key display switch * / ) | Switches the display of the machine function keys. |

Used to specify paper conditions for the paper tray. The specified conditions can be registered as a paper profile. | |

Corrects misalignment of printing positions on the front and back sides. | |

Adjusts colors or finishing of printouts. | |

Configures the settings related to Image Controller. This is displayed when Image Controller is mounted. | |

Configures settings for curl adjustment by Relay Unit RU-518m. | |

Displays the User's Guide on the Touch panel. | |

Sets the trimmer profile used when Trimmer Unit TU-510 is mounted. | |

Performs color density control at any time. You can perform color density control or manage the registered adjustment contents. | |

Used to check the periodic adjustment result of Color Density Control. | |

Adds, edits, or deletes a paper profile. | |

Check printing errors when Intelligent Quality Optimizer IQ-501 is mounted. | |

Check the automatic inspection result when Auto Inspection Unit UK-301 is mounted. | |

Check the reference image of the registered automatic inspection images when Auto Inspection Unit UK-301 is mounted. | |

Check the remaining memory space in this system and Auto Inspection Unit UK-301. | |

Sets the inspection standard or the operation to be performed in the case an error is detected in Intelligent Quality Optimizer IQ-501 when Auto Inspection Unit UK-301 is mounted. | |

Measures target paper, and sets the appropriate paper when the type or weight of the paper loaded in a paper tray is not known. | |

Used to specify sample printing conditions. You can check an output sample at the specified timing. | |

This function allows you to check reports related to this system, specify the network communication timeout, and configure the scan setting. |

in the upper-right of a page, it turns into

in the upper-right of a page, it turns into  and is registered as a bookmark.

and is registered as a bookmark.